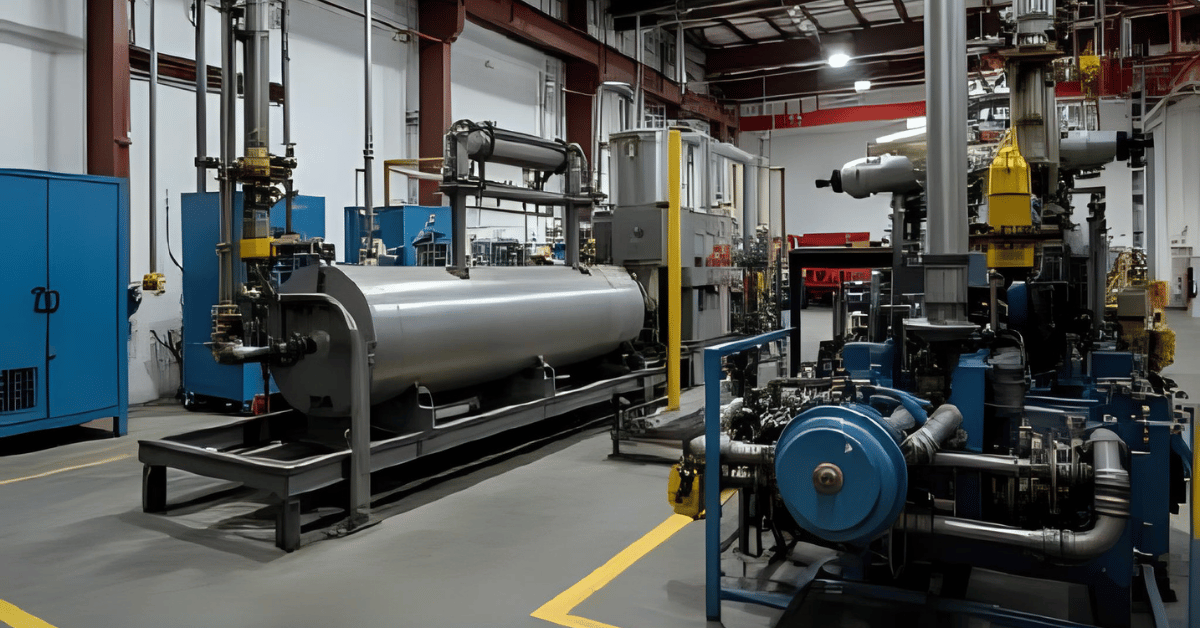

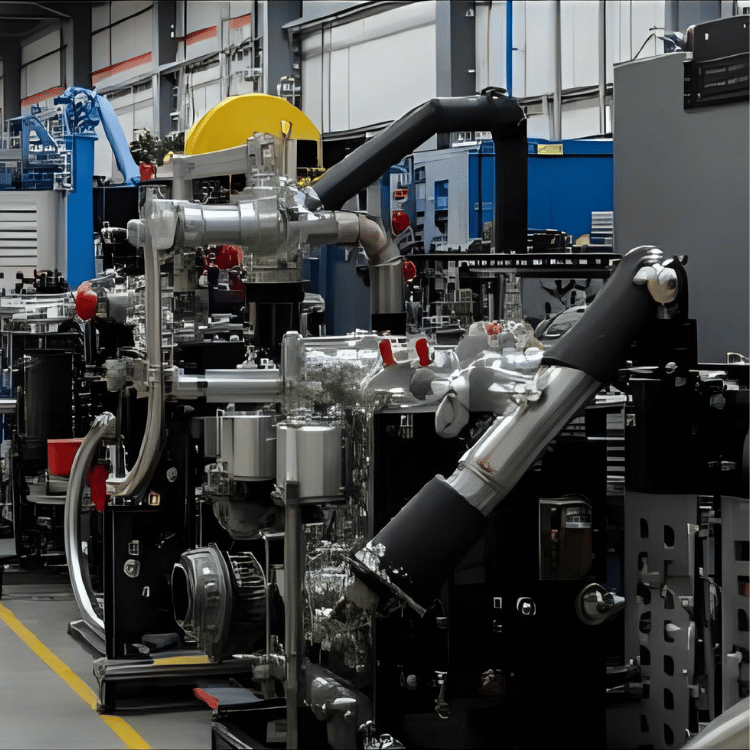

When a company reaches the point where operations outgrow their current facilities or strategic decisions demand a move, an industrial relocation becomes more than just a physical transition—it turns into a meticulous business operation requiring clarity, structure, and highly synchronized execution.

From managing downtime and equipment disassembly to transportation logistics and reassembly, the process can deeply affect productivity, revenue streams, and long-term success. That’s why companies in the Greater Tampa Bay area increasingly turn to experienced professionals like Big Boys Moving and Storage, with over two decades in the business, to ensure seamless transitions backed by real-world expertise.

Whether you’re expanding into a larger production space or shifting across town for regulatory or economic benefits, this article outlines actionable steps to manage your industrial relocation efficiently and without unnecessary setbacks.

The Business Drivers Behind Industrial Relocation

Not all moves are created equal. Industrial relocation typically stems from necessity rather than convenience. Understanding the “why” helps establish the framework for every step that follows.

Companies relocate for reasons such as:

- Outgrowing current space and facilities

- Reducing operational costs

- Meeting safety and compliance standards

- Accessing a more skilled labor pool

- Strategic proximity to suppliers or clients

- Modernizing outdated infrastructure

In each of these cases, the priority is minimizing disruption while maximizing efficiency throughout the move. It’s not just a matter of transporting machinery—it’s about transferring an entire ecosystem.

Strategic Planning for Industrial Relocation

Before the first machine gets unplugged or any inventory is moved, an effective relocation plan must be put into motion. This stage lays the groundwork for a successful execution and minimizes unanticipated complications.

Start with these critical areas:

- Internal stakeholder alignment

- Timeline development with built-in contingencies

- Inventory audits and asset classification

- Risk assessments and mitigation plans

- Equipment disassembly/reassembly protocols

- Vendor coordination and compliance oversight

A well-planned relocation hinges on tight coordination between departments—operations, IT, safety, and facilities management must work together from the earliest phases. Businesses that leave planning too late often face production delays and missed deadlines.

Key Personnel and Their Roles During an Industrial Relocation

Every industrial relocation needs internal champions. These aren’t just project managers—they’re integration specialists who understand the nuances of machinery, systems, and daily operations.

Appoint dedicated team members to oversee:

- Safety compliance and regulatory checks

- Equipment inspection and preparation

- Facility layout planning

- Vendor sourcing and logistics control

- IT system transfer and reconfiguration

Clear responsibilities reduce communication breakdowns and support accountability, which is especially important when external vendors are involved.

Risk Mitigation Tactics You Can’t Skip

Industrial relocation exposes businesses to more than just logistical challenges. Without a clear risk mitigation framework, companies may incur costly downtime, equipment damage, or data loss.

Consider these strategies:

- Create backup systems for critical operations.

- Insure high-value machinery during transit.

- Test systems at the new site before decommissioning the old one.

- Engage with compliance inspectors early to avoid post-move delays.

- Use professionals for disassembly, loading, and installation.

At Big Boys Moving and Storage, our team routinely handles machinery, robotics, and other technical equipment with precision, minimizing risk across each phase.

Why Industrial Relocation Timing Matters

Timing can make or break a relocation. It directly affects operational downtime, staff productivity, and your company’s bottom line. Moves should be scheduled during low production periods, holidays, or planned maintenance cycles whenever possible.

Coordinate timing across:

- Manufacturing cycles

- Vendor availability

- Site readiness

- Staff relocation and training

- Weather and transportation conditions

Align your move with periods of naturally lower activity to avoid disrupting revenue-critical operations. Companies who fail to do this often scramble mid-move, which adds cost and chaos.

Choosing the Right Vendor for Industrial Relocation

Not all moving companies are equipped for industrial relocation. The skillset required goes far beyond packing and lifting. You’re not just moving boxes—you’re moving workflow systems, production capacity, and technological infrastructure.

Look for a vendor that offers:

- Industrial-grade equipment handling

- Trained personnel in disassembly and reassembly

- Secure storage solutions

- Short-notice and emergency availability

- Proven experience with businesses of similar size

Big Boys Moving and Storage checks all these boxes. Being a family-owned business based in Tampa with 20+ years of experience, we understand the value of speed, precision, and accountability. Need last-minute support? We’ve got the team and tools to act fast.

The Financial Implications of Industrial Relocation

Industrial relocation impacts both fixed and variable costs. Budgeting properly avoids unwanted surprises.

Factors to account for include:

- Transportation and fuel charges

- Equipment downtime

- Staff overtime or temporary hires

- Licensing and permitting at the new location

- Post-move inspections and upgrades

Underestimating the financial commitment can stall projects midway. Companies should expect some margin of fluctuation and keep reserve funds for unforeseen issues.

Communication Tactics to Support Industrial Relocation

While planning and logistics are vital, communication is what holds everything together during an industrial relocation. Keeping staff and stakeholders in the loop reduces resistance and confusion.

Key communication steps:

- Inform employees early and provide regular updates

- Create a relocation FAQ sheet for staff

- Notify clients, vendors, and partners with clear timelines

- Use visual tools like layouts and timelines for clarity

- Designate point-of-contact personnel for every department

A cohesive message creates unity and streamlines collaboration across internal and external teams. Transparency builds trust—internally and externally.

Industrial Relocation Site Readiness Checklist

Arriving at a new location isn’t the finish line. The site must be fully prepped to accept your equipment and processes.

Verify readiness with this checklist:

- Electrical capacity and HVAC compatibility

- Floor load limits and ceiling clearances

- Loading dock availability

- Safety systems and signage

- Network and internet setup

- Permits and occupancy certifications

Skipping these checks leads to post-move downtime, which can be avoided with an early inspection and facility audit.

Post-Move Evaluation and Process Stabilization

Even after the last crate is unloaded, the job isn’t done. Performance benchmarks must be re-established, and staff need time to adapt.

Tasks to prioritize:

- Equipment recalibration

- Systems testing and diagnostics

- Staff orientation and retraining

- Vendor service confirmation

- Inventory reconciliation

Conducting a post-move audit helps verify that all operations are back online. This also offers a chance to improve layouts, workflows, and productivity in the new space.

Frequently Asked Questions About Industrial Relocation

How long does an industrial relocation typically take?

It depends on the size and complexity of the operation. Smaller moves can take days, while larger ones may span several weeks.

What’s the best time of year to plan a move?

Schedule moves during planned shutdowns, off-peak seasons, or holiday closures to reduce the impact on production.

Do I need permits for industrial relocation?

Yes. Building occupancy permits, transportation authorizations, and zoning compliance may be required depending on location.

How can I ensure equipment safety during transport?

Use professional movers who specialize in industrial relocations and verify insurance coverage for high-value items.

Can Big Boys Moving and Storage handle short-notice relocations?

Absolutely. We specialize in same-day and last-minute moving services across the Greater Tampa Bay area.

Ready to Move? Let Big Boys Handle the Heavy Lifting

If you’re preparing for an industrial relocation, don’t let the weight of logistics slow your momentum. Big Boys Moving and Storage offers experienced support for businesses across the Greater Tampa Bay area, delivering reliable service backed by 20+ years in the industry. From warehouse equipment to specialized machinery, we know what it takes to keep your business moving forward.

Call us today at 813-936-2699 or contact us online to get your tailored quote. With our team on your side, you can focus on growth while we handle the logistics.